Process Safety Blog

Applying Safety Assessment to Water Treatment Plants

When you think about the types of facilities and industries that require detailed process safety type hazard and risk analyses, Water Utilities don’t necessarily feature at the top of that list. High-hazard facilities for example within the Oil & Gas, Refining and Petrochemical industries, are now expected to be mature in process safety and have well-developed systems and adequate resources to assess and reduce their major process risks. There are however many other types of facilities, one of which being Water / Wastewater Treatment Plants (WTP), that store and process various hazardous substances that have the potential to cause serious process safety incidents on and off their sites.

WTPs are an essential part of everyday life, ensuring the water we consume is of the required quality or is clean enough to be released back into the environment. A typical wastewater treatment process will include receipt, screening, flocculation, sedimentation, biological treatment, clarifying, filtering and disinfection before release, as well as residual solid waste treatment. The water treatment process for consumption is slightly varied, with more dosing and treatment steps upfront and within the process to ensure water is of a quality suitable for human consumption.

Whilst the majority of the risks to the health and safety of workers on a WTP site are occupational, there are specific substances and more defined processes e.g. disinfection, on-site incineration, and biological/chemical treatment which have the potential to result in a process safety incident. Recently designed and installed treatment plants have incorporated the Hierarchy of Controls approach for these hazardous areas of their plant by changing to different technologies e.g. UV treatment for disinfection, or sodium hypochlorite instead of chlorine treatment. There are still however many older plants in service with chlorine disinfection, on-site incineration and/or hazardous chemical treatment.

|

|

|

|

| We can provide your company with an SMS Auditing service. Find out more HERE! | Find out about our upcoming HAZOP LEADER Training Course HERE! | Read how we can perform an independent SCE verification assessment HERE! |

Case study:

For the last year, I have been working with a company that owns and operates two water treatment facilities and one large wastewater treatment plant. Following a few incidents and near misses involving hazardous substances, site management recognised the need to improve their process safety culture through competency development, hazard and risk assessment, and management systems improvement.

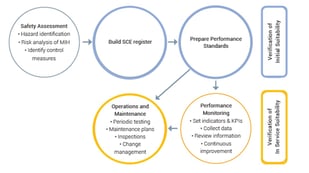

The Safety Assessment approach shown in the figure below was used to guide the process, which is a simple but methodical way of stepping through the process of hazard identification, risk assessment, reasonably practicable assessment, critical control identification and performance standards development:

The scope of the safety assessment packages was limited to areas processing hazardous substances e.g. chlorine treatment and sludge incineration that were more defined i.e. where P&IDs were available. An overall structured hazard analysis (HAZID) of each site was also done to identify other hazards that required further action or assessment beyond the process safety scope. This workshop also helped to get the team familiar with each other and their roles/contributions to the safety assessment process. A conventional HAZOP was performed on the chlorine storage and dosing systems to identify causes that had the potential for more severe consequences for people. Process safety incident scenarios were developed based on common causes that could be grouped and placed on bowties, which together with consequence modelling, formed the basis for the risk assessment. This risk workshop together with the SFAIRP assessment allowed the team to identify both current and possible additional controls that could be implemented to minimise the risks of these process safety incident scenarios. Finally, a list of critical controls was produced, for which performance standards could be developed to document the design, operating and maintenance requirements for these critical controls.

Overall, the structured safety assessment process proved extremely valuable by uncovering some common themes and the following general areas for improvement:

- Documentation and accuracy thereof, with a focus on understanding the design and operating limits of these hazardous systems

- The emergency response process, to incorporate learnings and actions from this process

- Management systems to ensure higher focus on current critical controls in place

- Decision-making regarding operating intent and new controls that could be implemented, with consideration for the hierarchy of controls

- Operating procedures and Maintenance instructions, which typically form the larger proportion of barriers to these types of plants

While there may already be established processes of assessing hazards, risks and criticality in other consequence categories e.g. drinking water quality, occupational safety, environmental and asset/operations; it was evident that this structured, yet simple safety assessment approach is transferrable also to these other areas of the business. Probably the most value that this process has brought was the opportunity and platform it provided for a multi-disciplined team to work together to improve the overall process safety of the site.

This is still a journey and there are various areas and systems of the overall site to be addressed, however, the initial findings and actions currently being progressed will only serve to improve the overall safety of workers at these WTPs. Get in touch if you’d like to hear more about this process.

Ready to take your process safety strategy to the next level?

Strengthen your plant’s risk management approach with our Safety Assessment Consulting for water treatment facilities. We help you identify hazards, assess risks, and implement effective controls tailored to your operations. Ensure your plant’s processes are systematically reviewed and compliant with best practice. Speak to us about HAZOP Leader Training for your water treatment operation

Have questions or need guidance? GET IN TOUCH. We're here to help.