Why the Distinction Matters

When incidents occur in industrial settings, the approach to investigation can define not only immediate responses but also long-term safety culture. Process Safety Incident Investigations and Occupational Health and Safety (OHS) Investigations differ in scope, methodology, and impact. While OHS incidents tend to be frequent, typically resulting in minor injuries or near-misses, process safety incidents are rare but carry potentially catastrophic consequences. This dichotomy calls for a different mindset, one that values both detailed technical scrutiny and an understanding of the broader organisational context.

Differentiating Process Safety and OHS Incidents

Process safety events can have massive consequences if early warnings are ignored, while OHS events tend to focus on individual safety risks that are more frequent but typically less severe. This fundamental difference shapes how investigations are conducted and how responses are structured.

Comparing Personal Safety vs. Process Safety

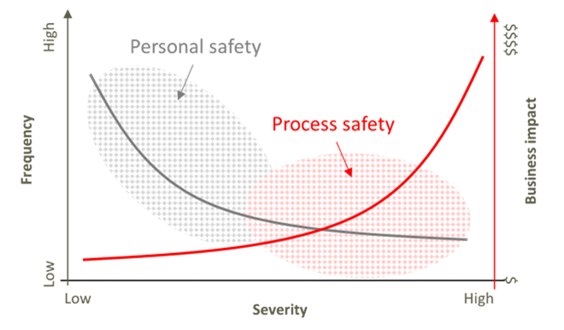

The image below provides a comparison of personal safety and process safety, illustrating their differences in frequency, severity, and business impact.

Figure: Personal Safety vs. Process Safety – Frequency, Severity, and Business Impact

In this graph:

· The grey curve represents personal safety, showing frequent but lower-severity incidents.

· The red curve represents process safety, indicating fewer incidents but significantly higher severity and business impact.

Categorising Process Safety Incidents

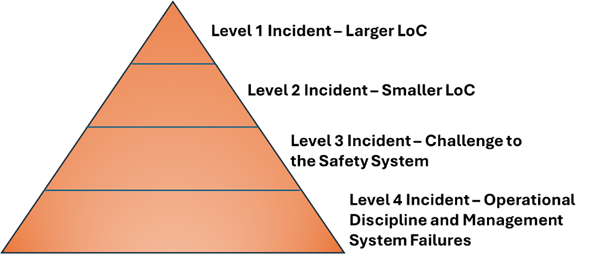

The API RP 754 categorisation divides process safety incidents into four tiers:

· Level 1: Large Loss of Containment (LoC)

· Level 2: Small Loss of Containment (LoC)

· Level 3: Challenges to safety systems

· Level 4: Operating discipline and management system performance issues

Figure: Process Safety Incident Pyramid

The pyramid segments incidents into tiers: from large losses in primary containment (Tier 1) to subtle signs of declining operational discipline (Tier 4). Each tier not only guides the investigative method, whether it is fault tree analysis or the “Five Whys” but also offers insight into potential vulnerabilities in the plant’s safety systems.

The Incident Investigation Process

Process safety incident investigations demand a rigorous, layered approach. They begin with a triage phase, where incident data, from physical evidence to interview findings and real-time system outputs, is scrutinised. This isn’t merely about pinpointing technical failures but also about identifying systemic and managerial gaps that can exacerbate risk over time.

Incident triaging is the first step in safety investigations. During triage, investigators sift through available data, from physical evidence and interviews to real-time process control data, to distinguish false positives from genuine hazards. This ensures proper prioritisation before a full investigation proceeds.

Building a strong incident investigation team is essential. Unlike general OHS incidents that might be led by safety advisors or operations personnel, process safety investigations require a lead with process safety expertise. Technical specialists help evaluate both immediate failures and systemic risks.

Information Gathering and Incident Investigation Techniques

Process Safety Incident Investigations rely on multiple sources of data, including:

- Physical Evidence – Examining damaged equipment and site conditions

- Interviews – Gathering firsthand accounts from personnel

- Real-time Data – Extracting insights from control systems (DCS, PI)

- Maintenance Records – Reviewing past equipment performance

- Design Information

The investigation methodology depends on the incident level. The following methods could be used:

· Levels 1 & 2: Techniques such as Fault Tree or Causal Tree analysis can be used

· Levels 3 & 4: Five Whys methodology could be used.

Some organisations without process safety expertise often rely on Occupational Safety-trained investigators who may use OHS techniques such as a ICAM which are not suitable for process safety incidents with a technical component.

Learnings and Corrective Actions

After an investigation, lessons learned must be communicated across the organisation using:

1. Detailed technical reports – Used for internal justification and regulatory communications.

2. Simplified summaries – Easier for broader audiences to understand and apply.

Failing to identify systemic contributors to the incident, such as leadership or budget constraints, can leave an organisation vulnerable to similar incidents in the future.

Final Thoughts

Process safety investigations are critical for preventing catastrophic industrial incidents. By deploying rigorous investigative methods, prioritising technical expertise, and ensuring a structured feedback loop, organisations can effectively reduce systemic risks while promoting a safer working environment.

Ready to take your process safety strategy to the next level?

Strengthen your organisation’s learning culture with our Process Safety Incident Investigation Training Course Build informed leadership that drives a strong safety culture, strengthen your board’s due-diligence capability with our Critical Risk Management for Directors & Executives Training Course.

Have questions or need guidance? Get in touch with our process safety consultants to discuss your facility risks and training needs.